In key areas such as construction, marine engineering, oil pipelines and bridges, corrosion is an "invisible killer" that threatens the safety and life of structures. How to extend the durability of metal materials in an economical and efficient way?

Zinc Wire has become the preferred material for global anti-corrosion projects due to its excellent anti-corrosion performance. This article will deeply analyze the working principle, application scenarios and how to choose high-quality suppliers of zinc wire to help you create safer and longer-lasting engineering projects.

Why choose Zinc Wire? Technological advantages of electrochemical anti-corrosion

Zinc wire provides active protection for metals such as steel through the principle of sacrificial anode. When zinc wire comes into contact with the protected metal, zinc reacts preferentially with oxygen and water to form a dense oxide layer, thereby blocking the corrosion of the substrate by the corrosive medium. This electrochemical protection technology is widely used in:

Marine engineering: salt spray environments such as docks, ships, and offshore platforms

Energy infrastructure: oil pipelines, storage tanks, and power towers

Transportation facilities: bridge cables, highway guardrails

Industrial equipment: hot-dip galvanizing process, steel structure welding

Compared with traditional coating anti-corrosion, zinc wire provides a longer protection period and does not require frequent maintenance, greatly reducing the cost of the entire life cycle.

How to choose high-quality Zinc Wire? Key indicators analysis

Zinc purity ≥ 99.995% : High-purity zinc ensures uniform electrochemical reaction and avoids local corrosion caused by impurities.

Compliance with international standards : ASTM B418, ISO 3549 and other certifications ensure material reliability.

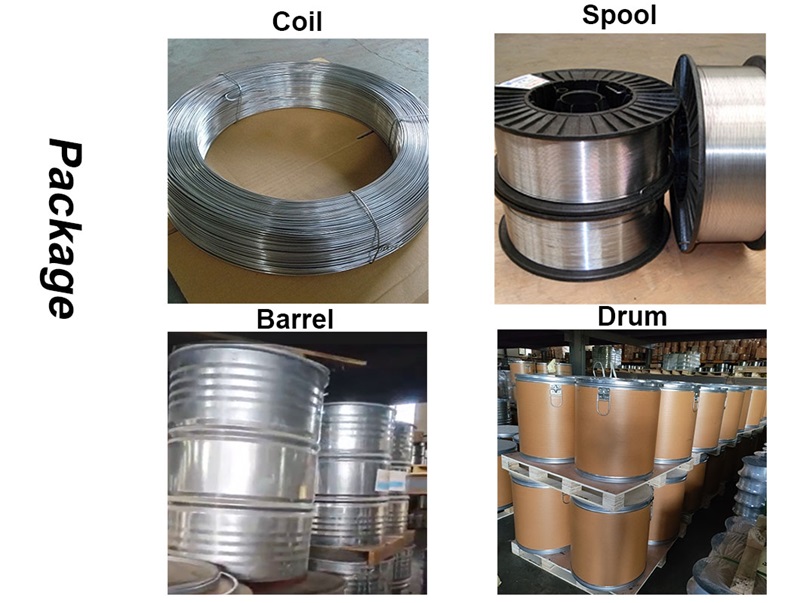

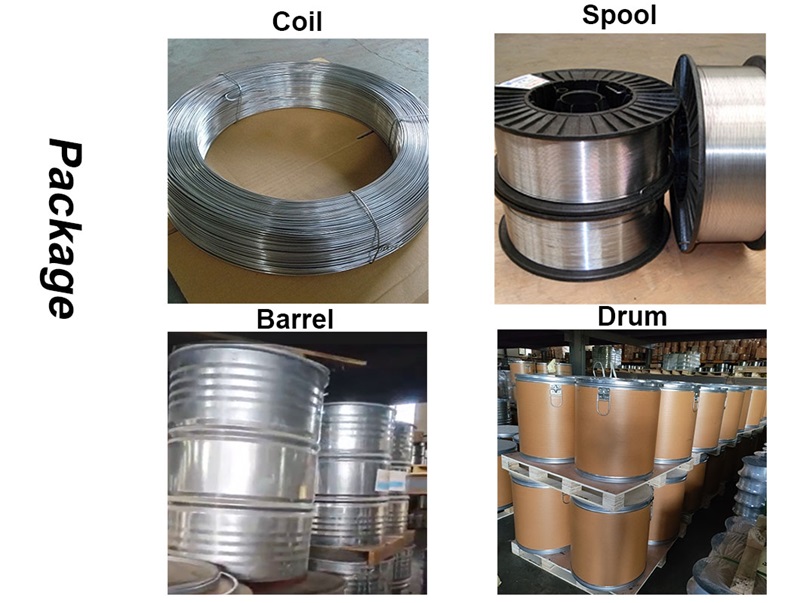

Customized specifications : Diameter (0.5mm-6mm), coil weight, and alloy ratio (such as Zn-Al alloy) need to be adapted to specific scenarios.

Surface treatment process : Bright annealing or plating technology can further improve weather resistance.

Choosing a supplier with a global supply chain and anti-corrosion engineering experience can ensure the performance stability of zinc wire in extreme environments.

Application Case: How does Zinc Wire protect global infrastructure?

Case 1: A submarine oil pipeline in the Middle East uses zinc wire + epoxy coating for dual protection, and its design life is increased to 50 years.

Case 2: The Nordic cross-sea bridge uses zinc wire thermal spraying to resist high humidity and freeze-thaw cycles, reducing maintenance costs by 60%.

Frequently Asked Questions (FAQ)

Q: What is the difference between zinc wire and other anti-corrosion materials such as zinc powder and zinc plate?

A: Zinc wire is more suitable for uniform coverage of complex structures, and has high construction flexibility. It can be used in conjunction with various processes such as thermal spraying and arc welding.

Q: What is the expected life of zinc wire anti-corrosion?

A: Depending on the environmental corrosion level, it is usually 15-30 years, and regular monitoring can further optimize the protection effect.

sophiashen@canchunmetal.com

whatsapp:+86-13722988404