What are the arc spraying cored wire ?

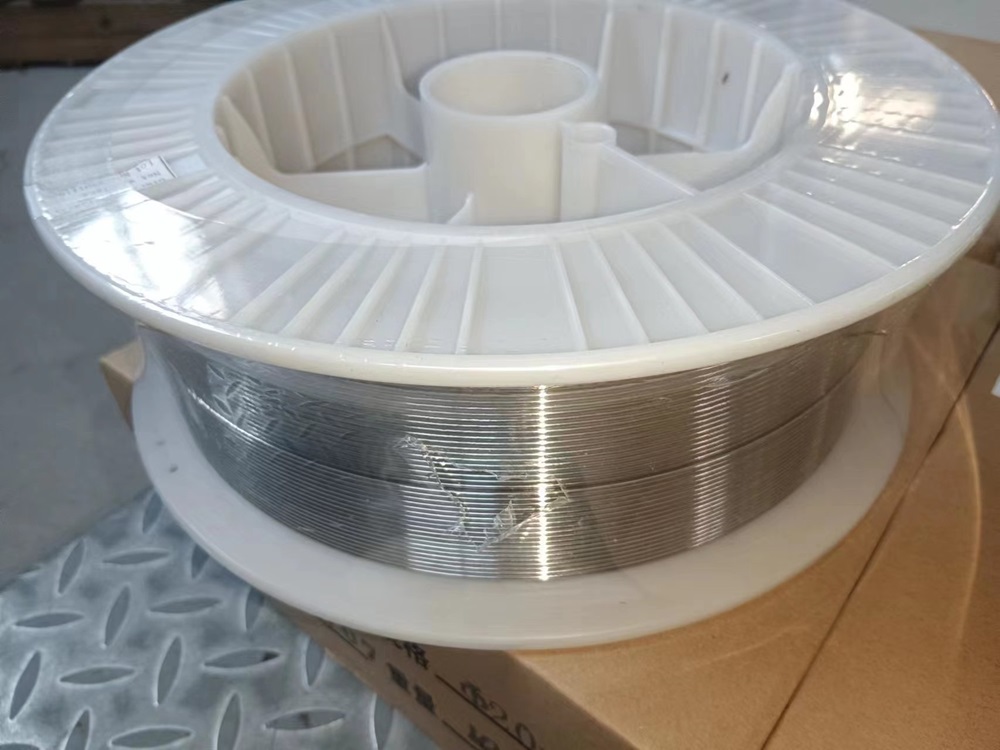

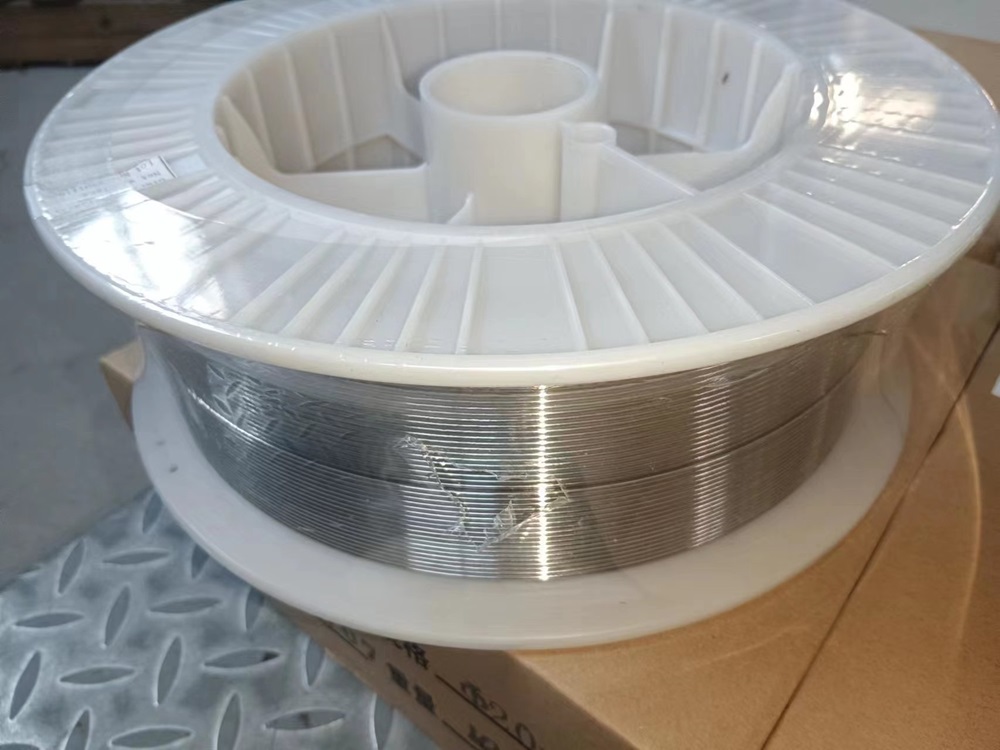

Arc spraying cored wire refers to a specific type of wire used in arc spray coating, a process where an electric arc is used to melt and spray metallic or non-metallic materials onto a substrate (such as steel or other metal surfaces) to create a coating. The "cored wire" part means that the wire consists of a metal sheath with a core made of a powder material. This core material could be a mixture of metals, alloys, ceramics, or other compounds, depending on the desired coating properties.

In arc spraying, the arc is created between two wires that are fed toward each other and the surface to be coated. The wires are melted by the electric arc, and the molten material is sprayed onto the substrate to form a coating.

Types of Cored Wire for Arc Spraying

Here are the main types of cored wire used in the arc spraying process:

1. Metallic Cored Wire

These wires are made of a metal outer shell (usually copper or aluminum) and have a core of metal powders that help improve the final coating properties.

Nickel-based Alloys: Common for applications requiring high corrosion resistance (e.g., marine environments or chemical processing).

Stainless Steel: Used for coatings that need both wear and corrosion resistance.

Bronze or Brass: Common for coatings requiring moderate corrosion resistance and wear resistance.

Aluminum Alloys: Typically used for corrosion protection in aggressive environments (e.g., marine applications).

2. Carbide Cored Wire

Carbide-based cored wires are used to achieve coatings with high hardness and wear resistance, which is particularly valuable in industries such as mining, manufacturing, and heavy equipment.

Tungsten Carbide: Provides exceptional wear resistance and hardness, making it ideal for high-impact applications.

Chromium Carbide: Offers similar benefits to tungsten carbide with excellent abrasion resistance and is often used in high-temperature environments.

3. Thermoplastic Cored Wire

These wires have a core of thermoplastic polymers or resins that melt during the spraying process, forming a strong bond between the coating and the substrate. They are useful for applications requiring less hardness but good adhesion and flexibility.

4. Composite Cored Wire

These wires are composed of a mixture of materials in the core, often combining metals with ceramics. This gives the coating enhanced properties such as corrosion resistance, wear resistance, or thermal stability.

Metal-Ceramic Composites: For example, a combination of metals with ceramic powders (like aluminum with ceramic materials) to create a coating with high durability and performance in extreme environments.

5. Zinc and Zinc Alloys

These cored wires are used for corrosion protection, often applied to steel structures. Zinc is a sacrificial material that protects the underlying metal from rust and degradation. Zinc coatings are commonly used in the construction and automotive industries.

Benefits of Using Cored Wires in Arc Spraying:

1.Enhanced Coating Properties: The core material can be carefully selected to achieve specific coating properties (e.g., corrosion resistance, hardness, wear resistance, etc.).

2.Efficient Process: Cored wire allows for a continuous feed, which can speed up the spraying process compared to traditional methods.

3.Improved Adhesion and Quality: The core material can enhance the adhesion of the coating to the substrate and provide more uniform coating quality.

4.Flexibility: Cored wires are available in many different combinations of core and sheath materials, allowing for tailored solutions for specific applications.

Common Applications of Arc Spraying with Cored Wire:

Corrosion Protection: For structures in harsh environments, such as bridges, pipelines, and marine equipment.

Wear-resistant Coatings: For heavy machinery, mining tools, and automotive components.

Thermal Barrier Coatings: In industries requiring high-temperature resistance, such as aerospace and energy sectors.

Arc spraying with cored wire provides an effective and versatile method for applying protective coatings that improve the performance and lifespan of metal parts and structures.

sophiashen@canchunmetal.com

whatsapp:+86-13722988404